One of the key differences between steel and concrete lies in the energy dissipation characteristics of steel under shear deformation. Steel exhibits a stable and predictable plastic behavior, which allows for consistent energy absorption during seismic events. Further studies have shown that even when plates experience partial instability, the energy consumed through bending deformation remains significant. By leveraging this property in structural design, it is possible to greatly enhance the efficiency of the structure. In particular, wall systems can be employed to increase the overall rigidity and load-bearing capacity of the framework.

Integrating light steel shear walls into a steel frame structure offers a practical and effective approach. These walls provide lateral stiffness and horizontal load resistance while also dissipating seismic energy efficiently. To ensure optimal performance, it's essential to determine the stiffness requirements and dimensional specifications for the stiffeners and the upper and lower beams connected to the shear wall. This helps in designing these edge elements with appropriate cross-sections and configurations, ensuring that the shear wall achieves the desired stiffness, bearing capacity, and stable energy dissipation capabilities.

A common issue in shear wall connections to upper and lower beams is slippage under cyclic horizontal loading. This often occurs due to the neglect of additional shear forces from overturning moments and the uneven distribution of bolt internal forces caused by shear lag effects. To address this, an improved method for calculating the internal forces in connecting bolts has been proposed, along with optimized configuration strategies. Experimental validation has demonstrated that this approach effectively prevents slippage and noise in high-strength bolted connections before the relative deformation angle exceeds 2%. This provides a reliable solution for implementing fully bolted connection systems, supporting modular construction and facilitating easy replacement after seismic damage.

By incorporating these design principles, engineers can create more resilient and efficient structures that not only perform well under seismic loads but also allow for easier maintenance and repair. This enhances both the safety and sustainability of steel-framed buildings, making them a preferred choice in modern construction practices.

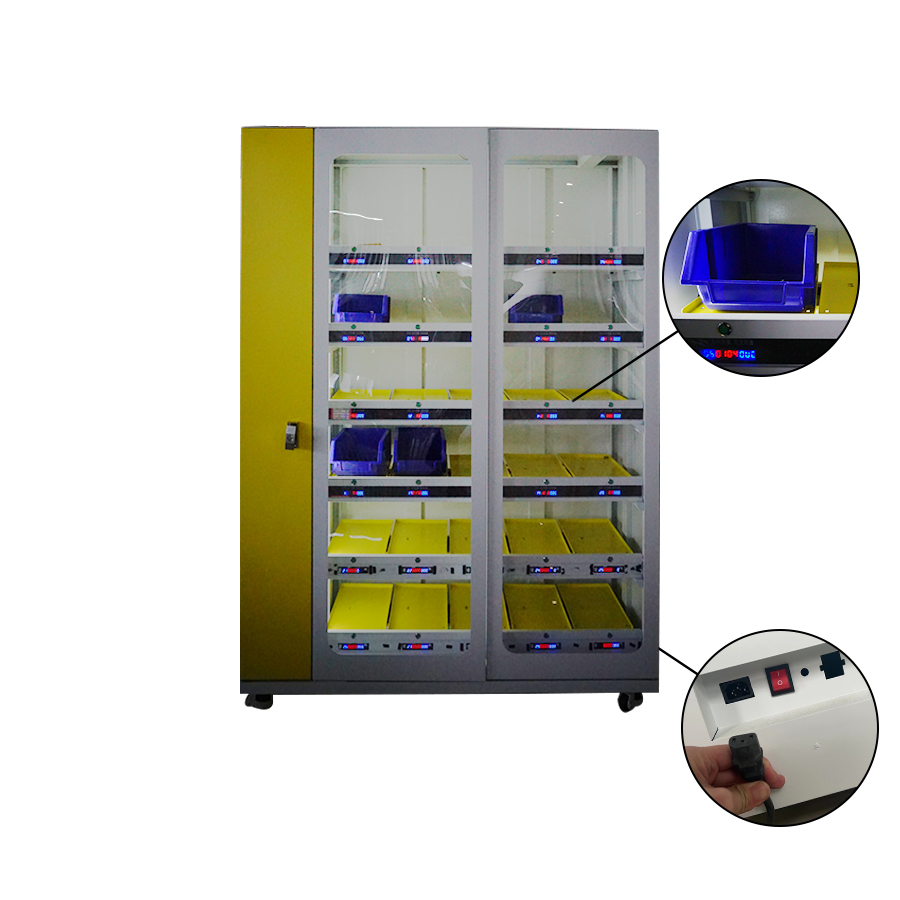

Weighing Cabinet

Enclosure: Weighing cabinets create a contained environment around the weighing balance, preventing hazardous materials from escaping into the laboratory.

Ventilation: Most weighing cabinets are equipped with ventilation systems that draw air into the cabinet, filter it, and exhaust it to the outside or recirculate it within the cabinet. This helps to maintain a safe and clean working environment.

Safety glass: The front panel of a weighing cabinet is typically made of safety glass to provide visibility while protecting the operator from potential hazards.

Ergonomic design: Weighing cabinets are designed to be comfortable and easy to use, with features such as adjustable height and tilt.

Built-in features: Some weighing cabinets may have additional features, such as built-in lighting, power outlets, and storage compartments.

Benefits:

Safety: Weighing cabinets protect the operator and the laboratory environment from exposure to hazardous materials.

Accuracy: The controlled environment within a weighing cabinet can help to ensure accurate and precise weighing results.

Compliance: Weighing cabinets are often required to comply with safety regulations and standards in industries such as pharmaceuticals, chemicals, and research.

Efficiency: By providing a dedicated space for weighing operations, weighing cabinets can improve efficiency and productivity in the laboratory.

Applications:

Pharmaceutical industry: Weighing cabinets are essential for handling and measuring pharmaceutical ingredients, ensuring product quality and safety.

Chemical laboratories: These cabinets are used for weighing chemicals and other hazardous substances in research and development settings.

Research laboratories: Weighing cabinets are valuable tools for scientists conducting various experiments and analyses.

Quality control: In industries where precision weighing is critical, such as food and beverage manufacturing, weighing cabinets are used for quality control purposes.

Types of Weighing Cabinets:

Standard weighing cabinets: These are general-purpose cabinets suitable for a wide range of applications.

Powder weighing cabinets: Designed specifically for handling powders, these cabinets often have specialized ventilation systems to prevent the spread of airborne particles.

Hazardous substance weighing cabinets: These cabinets are equipped with advanced safety features to protect operators from exposure to highly toxic or hazardous substances.

Factors to Consider When Choosing a Weighing Cabinet:

Safety requirements: Consider the specific hazards associated with the materials you will be handling and choose a cabinet that meets the appropriate safety standards.

Ventilation system: Evaluate the ventilation system to ensure it is adequate for your needs and complies with relevant regulations.

Size and capacity: Select a cabinet that is large enough to accommodate your weighing equipment and the materials you will be handling.

Ergonomics: Ensure that the cabinet's design is comfortable and ergonomic for the operator.

Additional features: Consider any additional features that may be beneficial, such as built-in lighting or power outlets.

By investing in a high-quality weighing cabinet, you can create a safe and controlled environment for your precision weighing operations, ensuring accurate results and protecting the health and safety of laboratory personnel.

Product color: White yellow (customizable)

Capacity: 30 scales

Freight lane type: 6 floors * 5 lanes

Weighing sensor: A single weighing position can weigh up to 20 kg, a small weighing capacity of 5g, and an error of 1gram

Applicable system: optional card swiping, facial recognition, and fingerprint recognition

Power supply: AC220V/50HZ

tool tracking, hazardous materials, precision weighing

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com